Refractory Ceramic Fiber

Ceramic fiber shaped module is a high temperature refractory material, usually used in the lining of industrial kilns. It is composed of compressed, folded or laminated ceramic fibers, and can be made into modules of various shapes and sizes according to customer requirements. It is lighter, easier to install and more durable than traditional bricks. At the same time, it also has excellent heat insulation performance and chemical corrosion resistance, and can withstand high temperature and chemical corrosion.

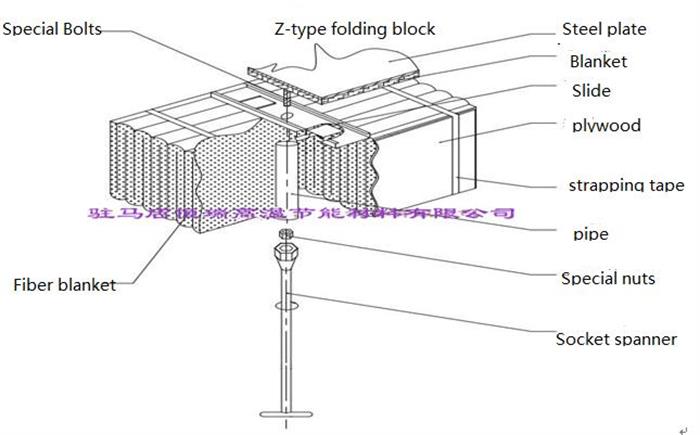

Ceramic fiber shaped module use the enhanced H-type anchors, which have greater strength, closer to the cold face. It can make sure the strength in high temperature. The fixed link was welding together with the high quality heat-resistance steel and stamping butterfly plate. The two round fixed link were embedded in the module system, enlarged the bearing area and ensured the firm of anchor system.

| Ceramic Fiber Shaped Modules | HR1050C-RM | HR1260ST-RM | HR1260HP-RM | HR1350HA-RM | HR1400LZ-RM | HR1430HZ-RM | HR1500Cr-RM | HR1600PCF-RM | |

| Max·Service Temperature | 1050 | 1260 | 1260 | 1350 | 1400 | 1430 | 1500 | 1600 | |

| 220kg/m3/at()℃/24hLinear Shrinkage Rate | ≤3.0(950℃) | ≤3.0(1000℃) | ≤3.0(1050℃) | ≤3.0(1200℃) | ≤3.0(1250℃) | ≤3.0(1300℃) | ≤3.0(1350℃) | ≤1.5(1450℃) | |

| (KG/M3)Density | 172/192/210/220/230/240 | ||||||||

| (W/m.k)Thermal Conductivity Rate | 400℃ | 0.14 | 0.09 | - | - | - | - | - | - |

| 600℃ | 0.20 | 0.16 | 0.16 | 0.16 | 0.16 | 0.15 | 0.15 | - | |

| 800℃ | 0.25 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.27 | |

| 1000℃ | - | - | 0.36 | 0.36 | 0.36 | 0.35 | 0.35 | 0.38 | |

| Chemical Composition(After burning) | Al2O3 | ≥38 | ≥42 | ≥45 | ≥52 | ≥37 | ≥37 | ≥37 | ≥72 |

| Al2O3+SiO2 | ≥97 | ≥97 | ≥98 | ≥98 | ≥92 | ≥83 | ≥93 | ≥99 | |

| ZrO2 | - | - | - | - | 5-7 | 15-17 | - | - | |

| Cr2O3 | - | - | - | - | - | - | 3-5 | - | |

| Others | ≤3.0 | ≤3.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.0 | |

| (Standard Size) | 600/300*300*300/250/200/150mm | ||||||||

| (Package) | (Non-fumigation pallet) | ||||||||

| Recommended using temperature: In oxidizing or neutral atmosphere, 100 ~250℃ lower than the maximum service temperature, In reductive atmosphere, 200 ~350℃ lower than the maximum service temperature. | |||||||||

Green energy industry:Waste incinerators, RTO exhaust treatment furnace, SCR environmental catalytic stove etc.

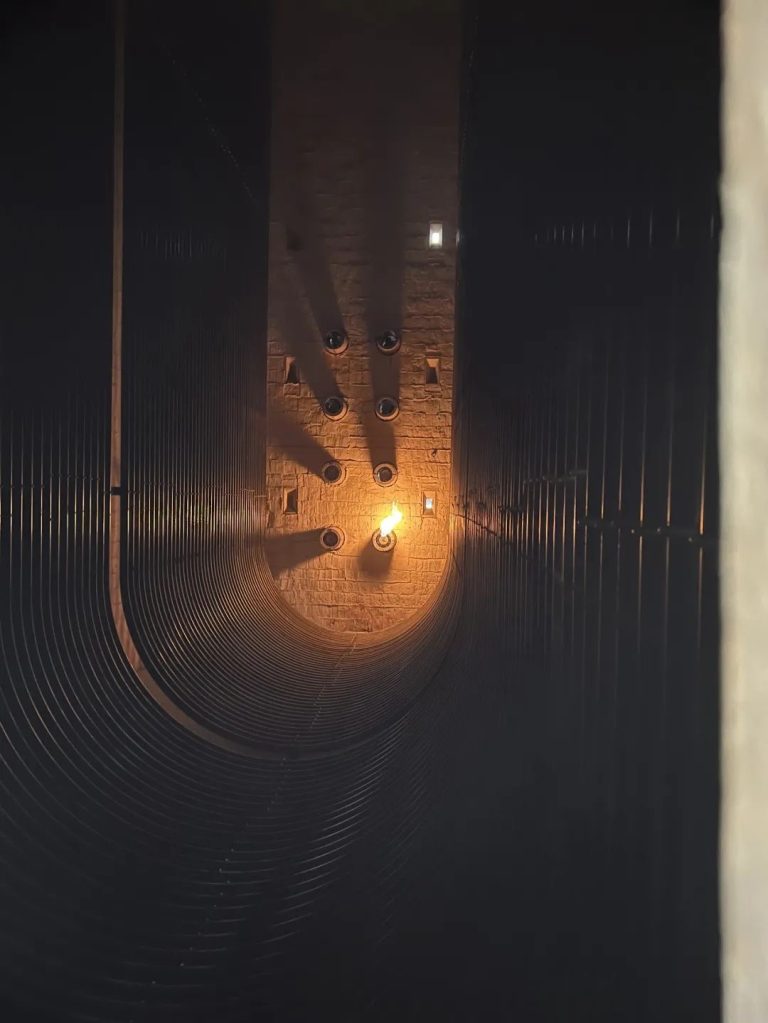

Ceramic Industry:Tunnel kiln, shuttle kiln, roller kiln.

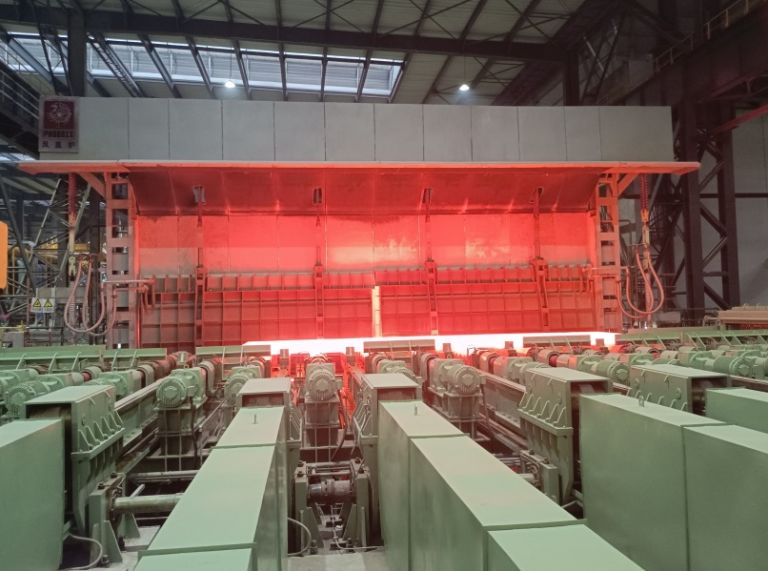

Iron and Steel Industry: Ladle cover, annealing furnace,rotary furnace,bell furnace,walking beam furnace,hot air and flue pipes etc.

Petrochemical Industry: Atmospheric furnace, transforming furnace, coking furnace, cracking furnace, flue etc.