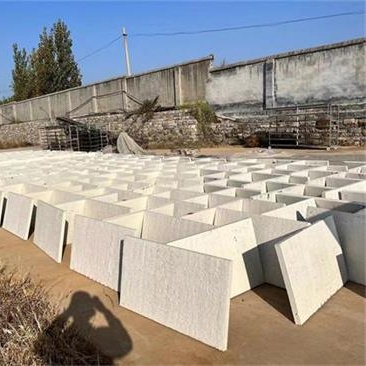

Refractory Ceramic Fiber

Hengrui ceramic fiber felt is made by wet vacuum forming. The strength of fiber felt is higher than ceramic fiber blanket and lower than ceramic fiber board, and the density is about 220kg/m³, so it can be used in the high-temperature field which has flexible requirements to products.

| Ceramic Fiber Felt | HR1050C-RF | HR1260ST-RF | HR1260HP-RF | |

| (℃)Max·Service Temperature | 1050 | 1260 | 1260 | |

| (KG/M3)Density | 200/220/240/260 | |||

| (24h)Linear shrinkage(After burning) | (900℃x24h)≤3.0 | (1000℃x24h)<≤3.0 | (1050℃x24h)<≤3.0 | |

| (%)loss on ignition | ≤10.0 | ≤8.0 | ≤8.0 | |

| (W/m.k)Thermal Conductivity Rate(Average 500℃) | ≤0.135 | |||

| Chemical Composition(After burning) | Al2O3 | ≥39 | ≥40 | ≥42 |

| Al2O3+SiO2 | ≥96.0 | ≥97.0 | ≥98.0 | |

| Others | ≤4.0 | ≤3.0 | ≤2.0 | |

| (Standard Size)mm(L*W*T) | 600*400*(20-50)mm | |||

| (Package) | (Carton or Pallet) | |||

Kiln construction: refractory material of internal lining (instead of fiber blanket).

Steel industry: the insulation of lining and mold.

Nonferrous industry: the pouring of copper and copper-bearing alloy.

Ceramic industry: internal lining of lightweight kiln car and furnace.

Glass Industry:Tempering Furnace insulating refractory.

Light industry: Industrial and domestic boilers combustion liner

Petrochemical industry: the lining of high-temperature heating furnace.