As a leading manufacturer of high-temperature insulation materials, Hengrui High Temperature provides refractory insulation solutions for equipment used in the production of silicon wafers and crystal materials. Our offerings include standard, zirconium-containing, and polycrystalline oxidation furnace ceramic fiber blankets, fiber vacuum-formed parts, and resistance wire heating modules for use in crystal growth furnaces, chain annealing furnaces, high-temperature oxidation furnaces, PECVD, and diffusion furnaces. But what exactly are the applications of ceramic fibers? This article will detail the primary applications and advantages of ThermalThal® ceramic fiber heating modules.

What is a ThermalThal® heater ?

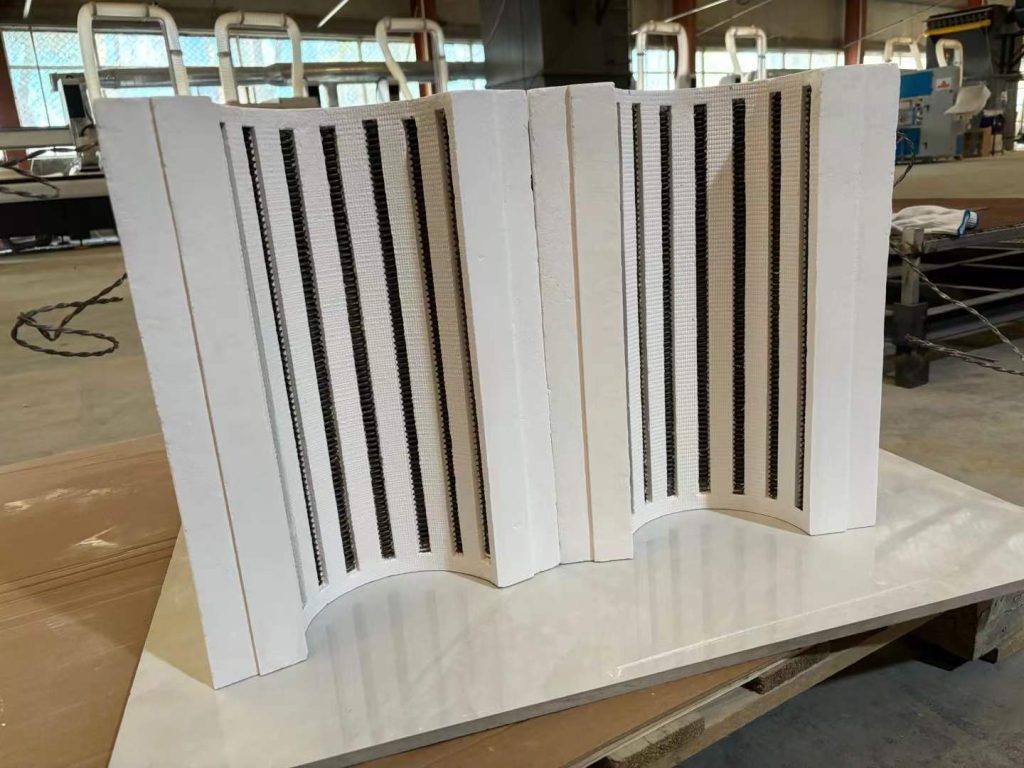

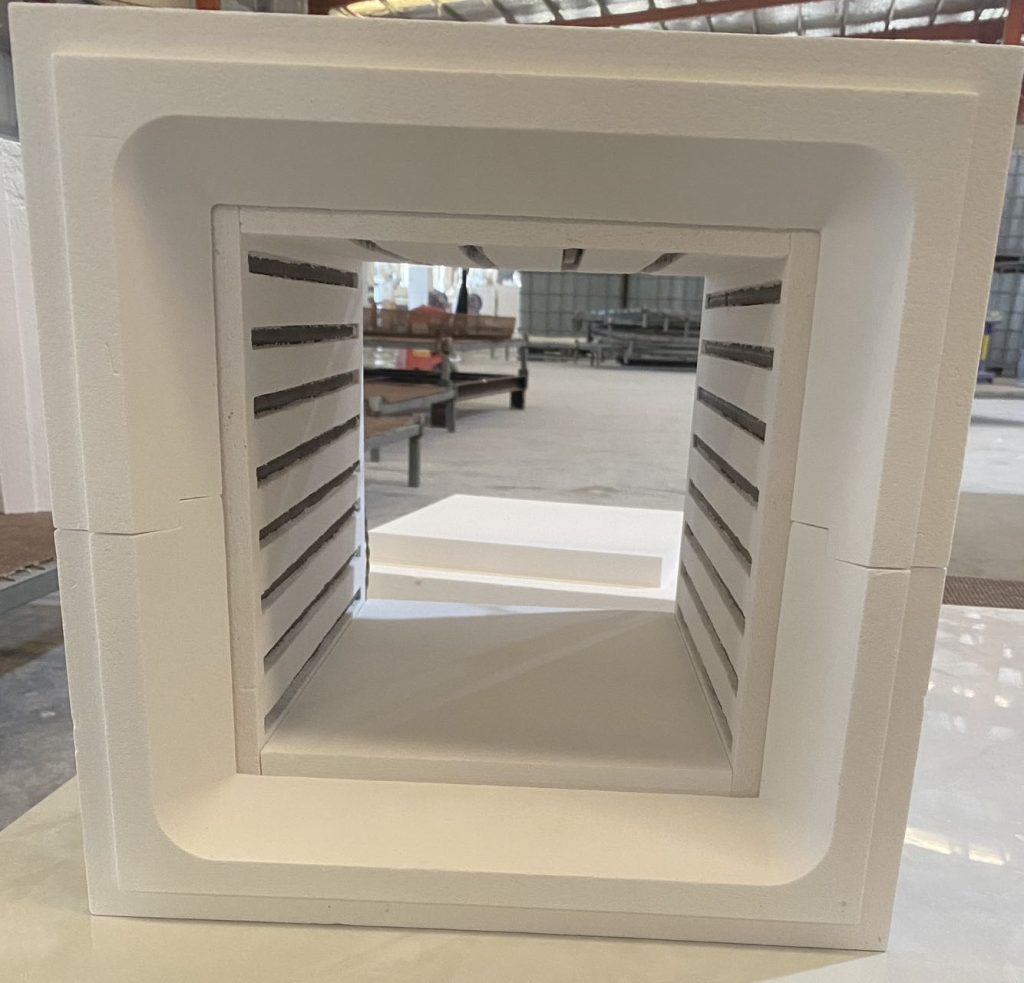

ThermalThal® ceramic fiber heater are integrated heating and insulation products made using vacuum adsorption molding technology. This process embeds or fixes electric heating alloy wires into refractory fiber materials. These ceramic fiber heaters can withstand temperatures up to 1300°C, offering excellent heating performance and thermal stability. They can be designed and provided with mature solutions tailored to different environmental needs.

Main Applications of ThermalThal® Heater

ThermalThal® heaters are widely used in various high-temperature heating equipment, including:

- Laboratory electric furnaces

- Industrial furnaces

- Powder metallurgy

- Oil pipelines

- High-temperature thermal processes in the photovoltaic semiconductor industry

Advantages of ThermalThal® Ceramic Fiber Heater

Traditional resistance wire heating furnaces use corundum tubes to thread the resistance wires. The connection points of the resistance wires need to be fixed with corundum tubes to prevent retraction at high temperatures. Over time or with impact, these fixed tubes can break, causing the resistance wires to retract and touch each other, leading to localized deformation, increased surface load, and eventual damage.

In contrast, the vacuum adsorption molding process embeds the resistance wires within the refractory fibers, securing them in place. This prevents deformation of the resistance wires under high-temperature fatigue, thereby extending their service life.

The ThermalThal® heaters, with their superior high-temperature resistance, insulation, and fireproof properties, are widely used in various industrial high-temperature equipment, pipelines, and electrical facilities. They are an ideal choice for many industries, providing reliable solutions for equipment insulation in high-temperature environments and fire protection in critical areas, ensuring safe and efficient operation.

By leveraging the exceptional properties of ThermalThal® heaters, industries can achieve enhanced performance and longevity of their high-temperature equipment, making them a valuable investment for any high-temperature application.