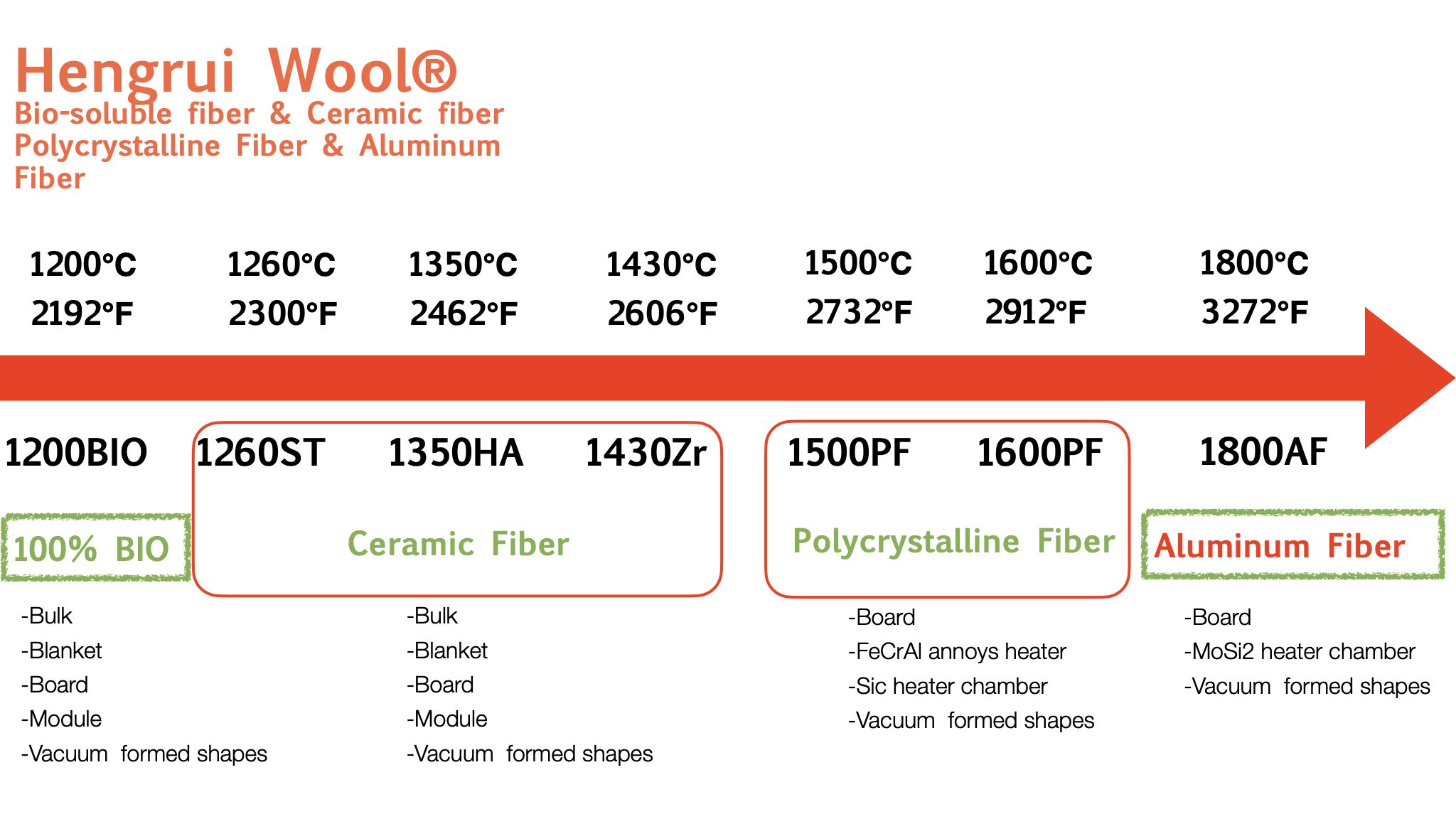

Hengrui Wool, a global leader in high-temperature insulation materials, offers a scientifically categorized product line designed to withstand temperatures ranging from 1200°C to 1800°C. Divided into four core categories—Bio-soluble Fiber, Ceramic Fiber, Polycrystalline Fiber, and Aluminum Fiber—these materials can be customized into forms such as Bulk, Blanket, Board, and vacuum-formed shapes. Tailored for industries like metallurgy, aerospace, and renewable energy, Hengrui Wool delivers efficient, eco-friendly thermal solutions.

Section 1: Hengrui Wool’s Core Fiber Categories & Products

1. 1200°C Bio-soluble Fiber

- Features: Eco-friendly, non-toxic, biodegradable, and compliant with industrial safety standards.

- Product Forms: Bulk, Blanket, Board, Module, Vacuum-formed shapes.

- Applications: Medium-low temperature furnace linings, pipeline insulation, chemical equipment thermal barriers.

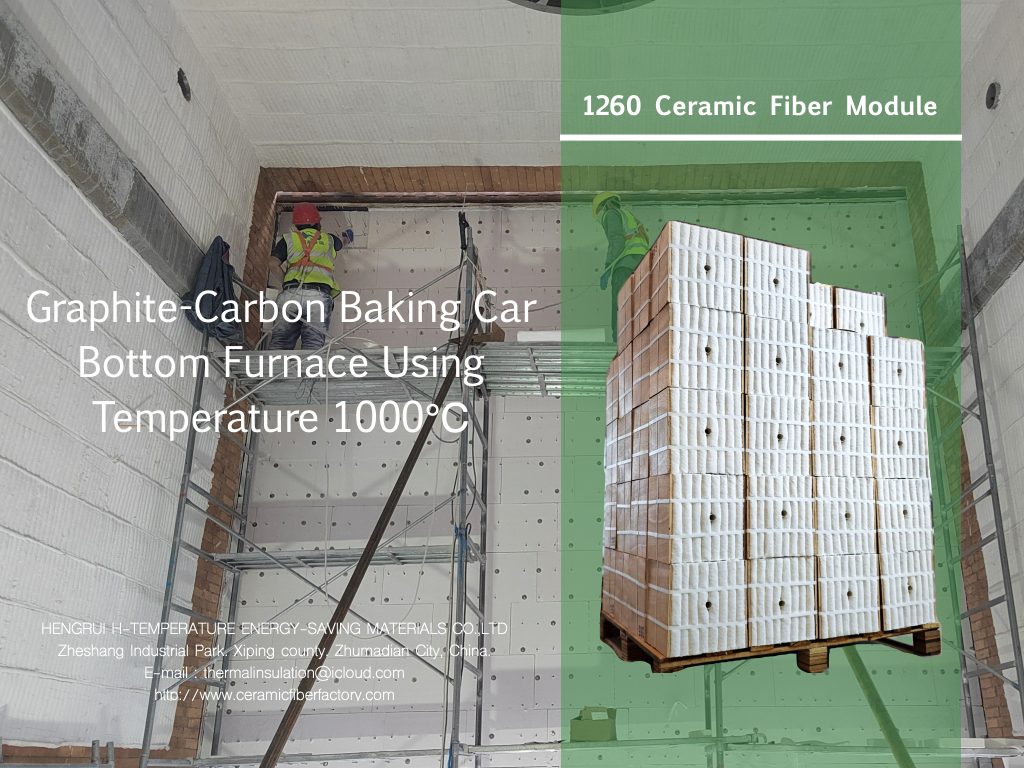

2. 1260°C/1350°C/1430°C Ceramic Fiber

- Features: Lightweight, low thermal conductivity, excellent thermal shock resistance.

- Product Forms: Bulk, Blanket, Board, Module, Vacuum-formed shapes.

- Applications: Steelmaking furnaces, glass melting kilns, heat treatment equipment.

3. 1500°C/1600°C Polycrystalline Fiber

- Features: Ultra-high temperature resistance, superior creep resistance for extreme environments.

- Product Forms: Board (high-temperature insulation panels), FeCrAl alloy heaters, SiC heater chambers, Vacuum-formed shapes.

- Applications: Semiconductor manufacturing, vacuum sintering furnaces, high-temperature electric heating elements.

4. 1800°C Aluminum Fiber

- Features: Industry-leading temperature resistance, unmatched stability, and mechanical strength.

- Product Forms: Board, MoSi2 heater chambers, Vacuum-formed shapes.

- Applications: Aerospace engine insulation, ultra-high-temperature R&D equipment, photovoltaic monocrystalline furnaces.

Section 2: Why Choose Hengrui Wool? 3 Key Advantages

- Precision Temperature Adaptation

Full coverage from 1200°C to 1800°C ensures optimal material performance without redundancy or deficiency. - Customizable Forms for Complex Needs

Available in 5 base forms (Bulk, Blanket, Board, etc.) and specialized vacuum-formed shapes to fit unique industrial designs. - Sustainability Meets Efficiency

Bio-soluble fibers reduce environmental impact, while ceramic and polycrystalline fibers enhance energy efficiency, supporting green manufacturing goals.

Section 3: Global Applications: Hengrui Wool in Action

- New Energy Sector: 1500°C polycrystalline fiber boards in lithium battery cathode material sintering furnaces reduce energy consumption by 18%.

- Metallurgy: 1430°C ceramic fiber modules extend the lifespan of electric arc furnace linings by 30%.

- Aerospace: 1800°C aluminum fiber vacuum-formed parts for rocket nozzle insulation systems pass NASA’s extreme-condition testing.

Conclusion: Conquer Extreme Heat with Tailored Solutions

Hengrui Wool combines scientific classification and cutting-edge technology to deliver precision-engineered insulation solutions. Whether you require standard products or complex custom components, our engineering team ensures the perfect balance of performance and cost efficiency.

Contact Hengrui Wool experts today for free technical consultation and sample testing!