Ceramic Fiber Insulation Boards Have Important Applications in Photovoltaic Screen Printing, Drying and Sintering Equipment

Ceramic fiber materials have excellent high-temperature resistance and thermal stability. They are suitable as thermal insulation in drying and sintering equipment used in the photovoltaic industry. The ceramic fiber insulation can effectively reduce heat loss from the equipment.

Furthermore, ceramic fibers exhibit good thermal insulation and heat conduction properties, which can help improve the thermal efficiency of the equipment. Additionally, ceramic fibers have excellent corrosion resistance and chemical stability. These properties effectively prevent equipment damage from chemical exposure.

In summary, the application of ceramic fiber materials in photovoltaic screen printing, drying and sintering equipment not only improves the performance and efficiency of the equipment. It also extends its service life.

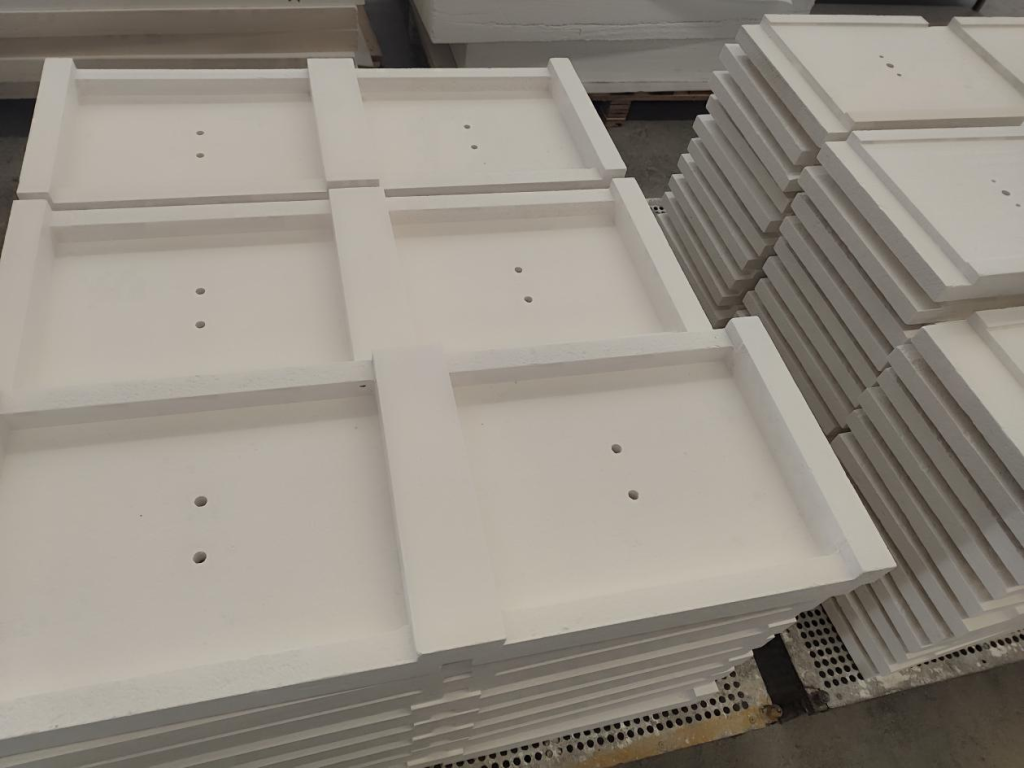

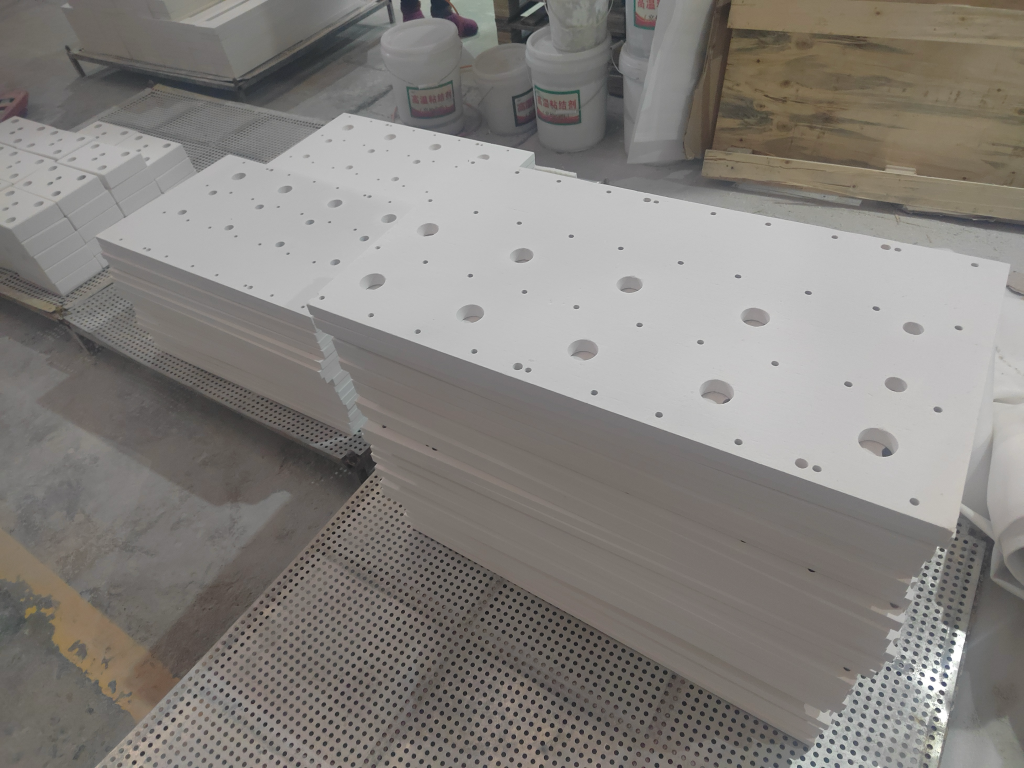

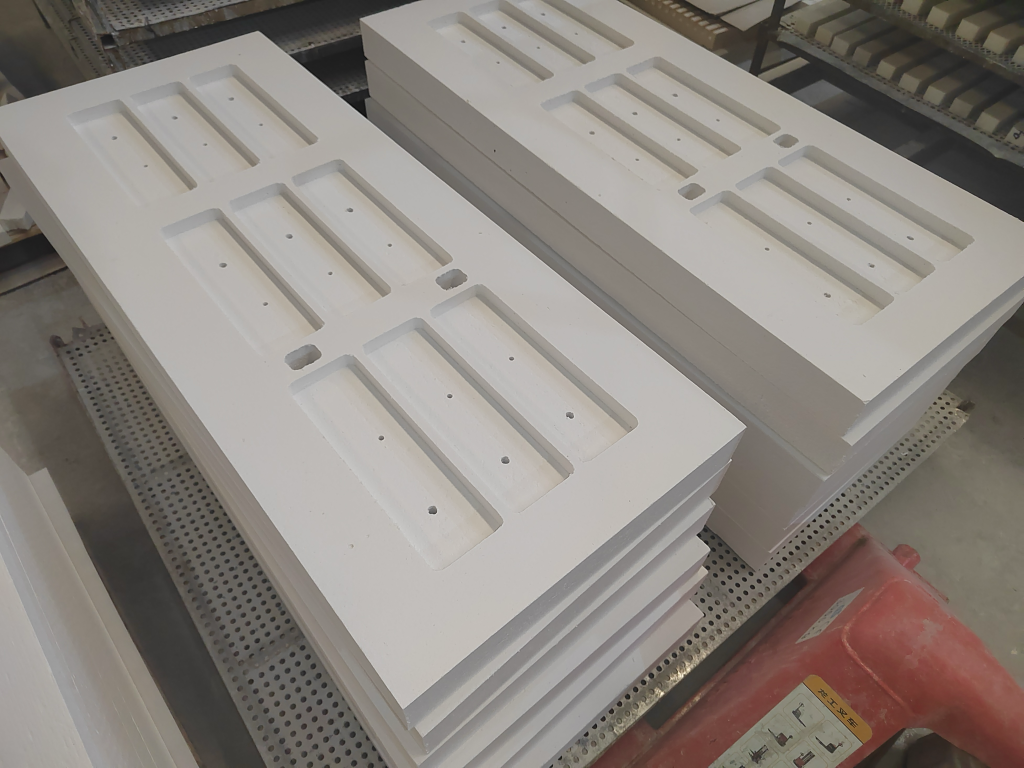

Ceramic fiber boards also have high strength and good machinability. They can be customized to specific sizes based on customer requirements. Our company is able to fabricate these customized ceramic fiber components according to customer needs.

Diffusion Furnaces Play a Key Role in the Photovoltaic Industry

Diffusion furnaces are a critical piece of equipment used in the manufacturing of solar cells. Their function is to form the p-n junction structure on the surface of solar cells. This is the region of charge separation (positive and negative charges) and it enables the photovoltaic effect.

The diffusion furnace, through controlled high temperatures and doping gas, transforms the pure silicon material on the surface of silicon wafers into p-type or n-type silicon with impurities.

This action of the diffusion furnace creates the p-n structure on the solar cell surface, with the p-type region being rich in positive charges and the n-type region being rich in negative charges, forming an electric field. When light shines on the solar cell surface, the energy of the photons excites electrons, and the electric field separates the electrons and holes, generating an electrical current. Therefore, the role of the diffusion furnace is to provide the conditions for charge separation in the solar cell. These conditions enable the photoelectric conversion.

Refractory fiber-adsorbed resistance wire furnace chambers play an important role in photovoltaic diffusion furnaces. They can withstand temperatures up to 1500°C. Through a rational design of the heating wire arrangement, the heating wires are adsorbed onto the refractory fiber furnace chamber. This design achieves uniform heating, fast heat dissipation, and long-term stability of the heating wires without deformation. It meets the process design requirements.